Robert LeHay purchased our SuperMax 25×2 ES Dual Drum Sander. He was kind enough to share his thoughts on our sander, as well as the work he uses it for.

Robert LeHay purchased our SuperMax 25×2 ES Dual Drum Sander. He was kind enough to share his thoughts on our sander, as well as the work he uses it for.

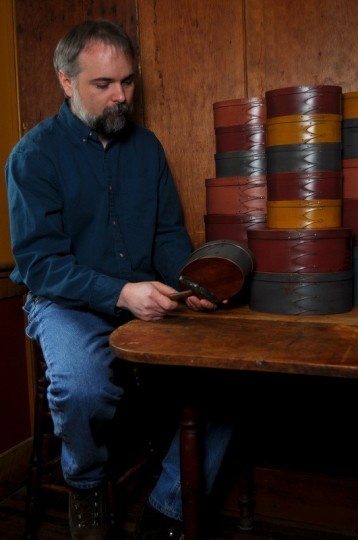

LeHay’s Shaker Boxes has been handcrafting reproduction Shaker boxes and carriers since 1993. Our products are made with traditional materials and are painted with an aged finish. Since 1993 we’ve sold our products to individuals, museum and retail shops, catalog companies, as well as a couple of appearances on QVC – just to name a few.

A Shaker box is made up of four pieces of lumber. Each box consists of a hardwood band (roughly 1/8” thick) wrapped around a thicker bottom board which is typically oval in shape. A cover of similar construction is then made to fit snugly over the top of the container. Although Shaker boxes and carriers are used mainly for decorative purposes today, they were originally used for storing kitchen ingredients, sewing materials and similar purposes. The most identifying characteristic of a Shaker box are the “fingers” or “swallowtail” joints made at the point where the band overlaps itself.

To produce the lumber for the boxes I elect to start with raw logs and hire a local sawyer with a portable bandsaw mill. The material for the bands will be sawn slightly over 1/8” of an inch thick. This lumber is allowed to air dry for a few weeks and is then sawn to the correct length and width. Since the material is so thin it can’t be run through a typical planer – and instead needs to be run through a sander to be abrasive planed.

In the 1990’s I purchased two Performax drum sanders (the predecessor to today’s SuperMax Line). The first was similar to today’s model 19-38 – which worked very well – however in the pursuit to speed up production I sold this machine and purchased a dual drum sander similar to a model 25×2. I used this for several years until it went to a new owner – the last I knew he was still using it.

With the construction of a new workshop in 2013 I purchased a SuperMax 25×2 ES. It’s only purpose in life being to abrasive plane maple band stock. I will typically run the lumber through the sander three times. The first time with 36 grit sandpaper on the first drum and 60 grit on the second drum – this gets the boards to the same starting thickness. The next two runs (one run on each side of the board) consists of an 80 grit on the first drum and a 120 grit on the second drum – this puts a smooth finish on both sides and gets the boards to the final thickness required.

With the construction of a new workshop in 2013 I purchased a SuperMax 25×2 ES. It’s only purpose in life being to abrasive plane maple band stock. I will typically run the lumber through the sander three times. The first time with 36 grit sandpaper on the first drum and 60 grit on the second drum – this gets the boards to the same starting thickness. The next two runs (one run on each side of the board) consists of an 80 grit on the first drum and a 120 grit on the second drum – this puts a smooth finish on both sides and gets the boards to the final thickness required.

When it came time to purchase a drum sander for my new workshop I did shop around. I found that pricing of the SuperMax brand of sanders was very competitive. Another factor was that some competitor’s sanders weren’t capable of sanding stock down to the thickness I’m looking for (the thinnest stock I run is roughly .062”). This in addition to my previous experience with this brand made my decision fairly easy.

I would also like to say that support after the sale is top notch. After receiving my new sander I had an issue with the conveyor motor (my fault). I called up Bill fully expecting I would pay for the part since it was not the fault of the machine or the quality of the build. Not only did he send the part free of charge but also paid for the shipping of the new part as well as the return shipping of the part I damaged. No questions asked.

I would also like to say that support after the sale is top notch. After receiving my new sander I had an issue with the conveyor motor (my fault). I called up Bill fully expecting I would pay for the part since it was not the fault of the machine or the quality of the build. Not only did he send the part free of charge but also paid for the shipping of the new part as well as the return shipping of the part I damaged. No questions asked.

If anyone would like further information as to how I use the sander, or any further recommendations please feel free to contact me. All my contact information is on my website at www.lehays.com

Sincerely,

Robert LeHay